Large Capacity Industrial Dough Mixer

Tilting Dough Mixer

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

The Tilting dough mixer is a supporting equipment for the production of foods such as bread toast, baguettes, and mooncakes. It can be connected to large-scale automated production lines,enabling automated production. Featuring a fully intelligent touch screen control system with automatic programming settings, it offers a luxurious and attractive appearance and convenient operation. With time selection and speed conversion functions, the industrial dough mixer ensures that the dough achieves the most ideal state of elasticity, water absorption, and expansion force. Customers can choose the corresponding model and specifications based on their production capacity. KC-SMART is a leading China industrial dough mixer supplier, which has the ability to provide large-scale model production with fixed production requirements.

Large Capacity Industrial Dough Mixer Specifications

| Product Name | Tilting Dough Mixer | ||||

| Model | KCFH-50 | KC-FH-75 | KC-FH-100 | KC-FH-120 | KC-FH-150 |

| Voltage | 5.6/1.5kW | 9/1.5kW | 10.5/1.5kW | 13.5/2.2kW | 15/2.2kW |

| Power | 380V3N | 380V3N | 380V3N | 380V3N | 380V3N |

| Dough | 80 | 120 | 160 | 200 | 250 |

| Flour | 50 | 75 | 100 | 120 | 150 |

| Rotational Speed | 120/240 | 120/240 | 120/240 | 120/240 | 120/240 |

| Weight | 850 | 1100 | 1200 | 1350 | 1500 |

| OEM/ODM | Accept | ||||

| Compay Nature | China Manufacturers Suppliers Factory | ||||

Large Capacity Industrial Dough Mixer Advantage

With a focus on innovation and quality, we produce a wide range of machinery, including our customized industrial dough mixer. Each mixer is designed to handle large batches with precision, ensuring consistent dough texture while reducing labor and enhancing production speed.

High Efficiency in Production

Our industrial dough mixer is significantly more efficient than ordinary mixers. It reduces working hours and saves manpower, achieving efficient production. This efficiency is crucial for high-volume operations, allowing businesses to produce more in less time while minimizing labor costs.

Advanced Electronic Control System

The Industrial Dough Mixer features an electronic control system with a lower maintenance rate and longer service life compared to traditional mechanical buttons. Additionally, a touchscreen control system is available, providing an intuitive and user-friendly interface. This advanced control system enhances operational convenience and reliability.

Humanized Design with Hydraulic Function

The hydraulic automatic rising and lowering function is a standout feature of our dough mixer. This hydraulic system provides a more humanized design, making it easier and safer for operators to handle large batches of dough. It reduces physical strain and improves overall usability.

Durable Imported Belts

We use high-quality imported belts in our Industrial Dough Mixer. Regular maintenance is performed to adjust the tension, ensuring long-term use without the need for frequent replacements. This not only saves on maintenance costs but also ensures consistent performance over time.

Food-Grade Stainless Steel Mixing Bowl

The mixing bowl is made using food-grade stainless steel one-time stretching technology. This manufacturing process results in a sturdy and durable bowl that is resistant to wear and tear. It ensures food safety and hygiene while maintaining the quality of the dough.

Special High-Strength Stainless Steel Dough Hook

The dough hook is crafted from food-grade, special high-strength stainless steel. This material choice ensures that the hook is both durable and safe for food processing. It can withstand the rigors of mixing large batches of dough without deforming or corroding.

Reliable Foreign-Branded Motor

Our Industrial Dough Mixer is equipped with a motor from a reputable foreign-owned brand. This high-quality motor has a service life that is 10 times that of domestic motors. It provides reliable power and ensures the long-term stability of the mixing process, reducing downtime and maintenance needs.

Large Capacity Industrial Dough Mixer FAQ

Q: What are the main differences between your Tilting Dough Mixer and the Tilted Double-Hook Dough Mixer?

A: Our Tilting Dough Mixer achieves uniform mixing of dough through the flipping of the cylinder, suitable for handling large quantities of dough with easy operation. The Tilted Double-Hook Dough Mixer, on the other hand, uses a double-hook design that more effectively stretches and folds the dough, ideal for pasta making that requires higher dough gluten content. Both are equipped with high-performance motors for long-lasting use.

Q: How do you achieve a motor lifespan that is 10 times that of a regular dough mixer?

A: We utilize advanced motor technology and high-quality materials in manufacturing, combined with rigorous quality control and durability testing, to ensure that the motor maintains high efficiency and stability even under continuous high-load operation. Additionally, our motor design focuses on heat dissipation and reducing wear, significantly extending its lifespan.

Q: Are the belts of your dough mixers imported? How often do they need to be replaced?

A: Yes, the belts of our dough mixers are made of imported materials, featuring wear resistance and anti-aging properties. As long as you follow the recommended regular maintenance in the user manual, the belts can typically last for a long time without needing replacement.

Q: Are these two dough mixers suitable for home use or more suitable for commercial kitchens?

A: Both dough mixers are designed with powerful mixing capabilities and durability, making them more suitable for commercial kitchens, especially in restaurants, bakeries, and food processing factories that require large quantities of dough. However, they can also handle the demands if you frequently make large amounts of pasta at home.

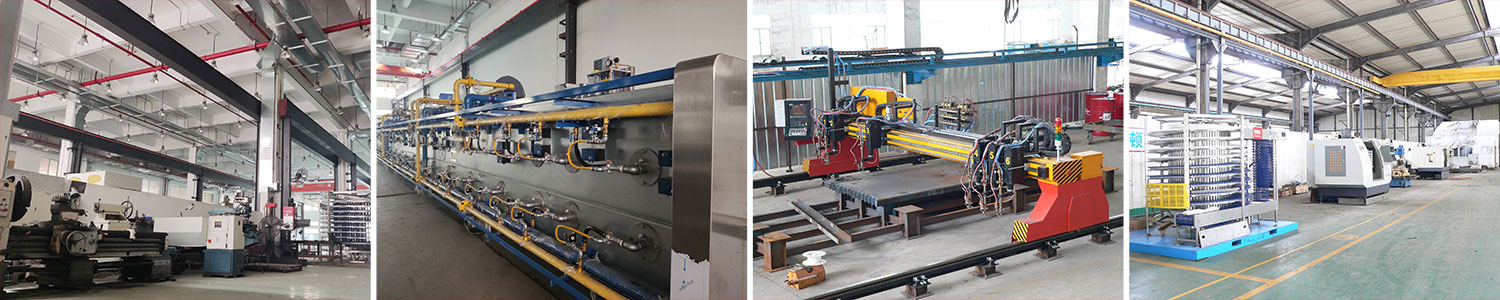

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

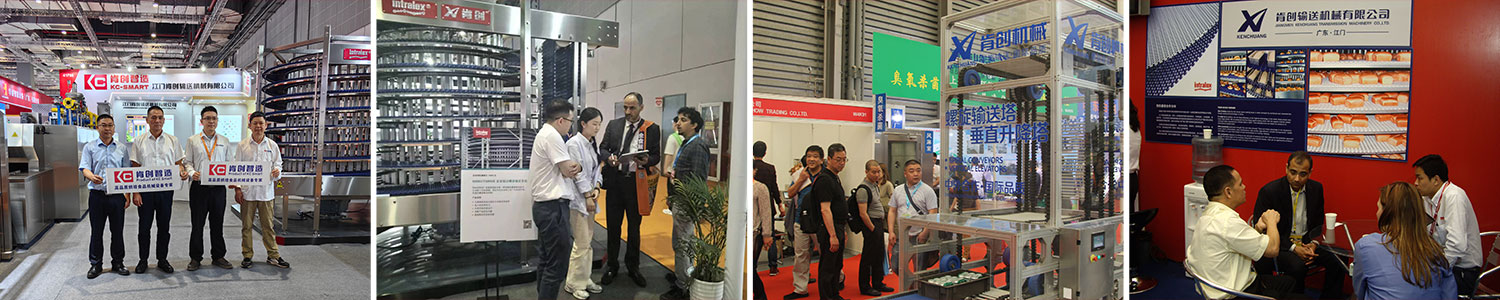

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.